Mayrc

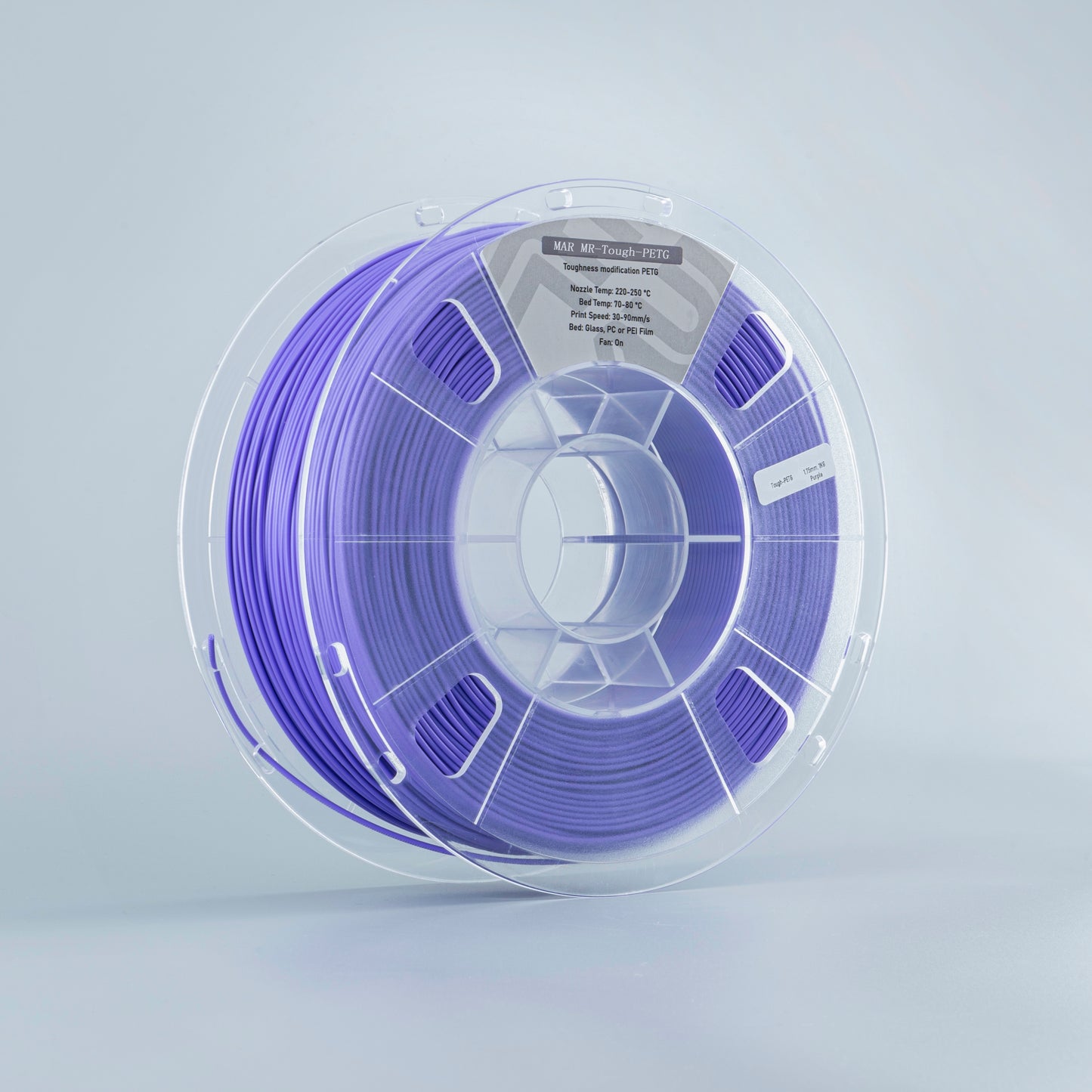

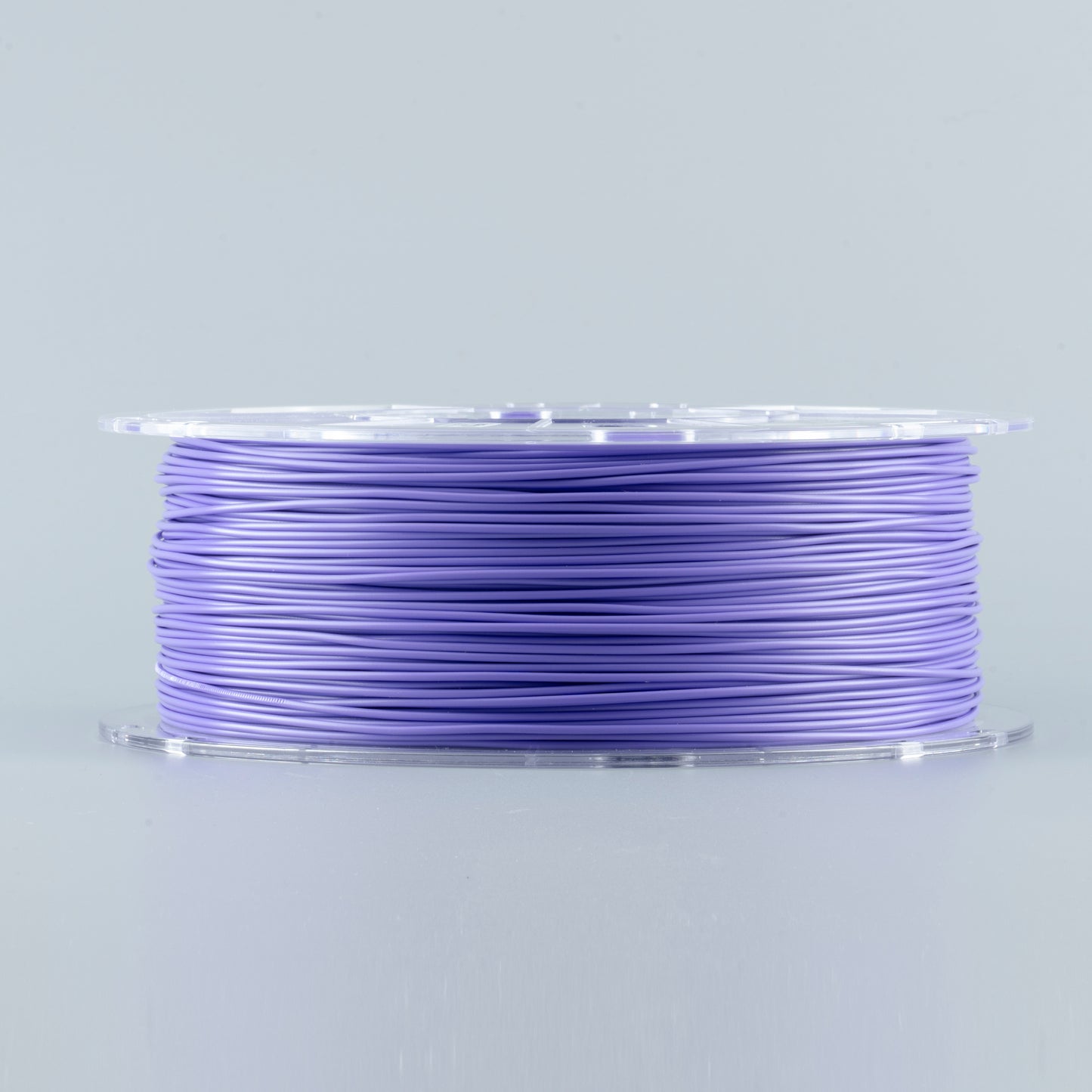

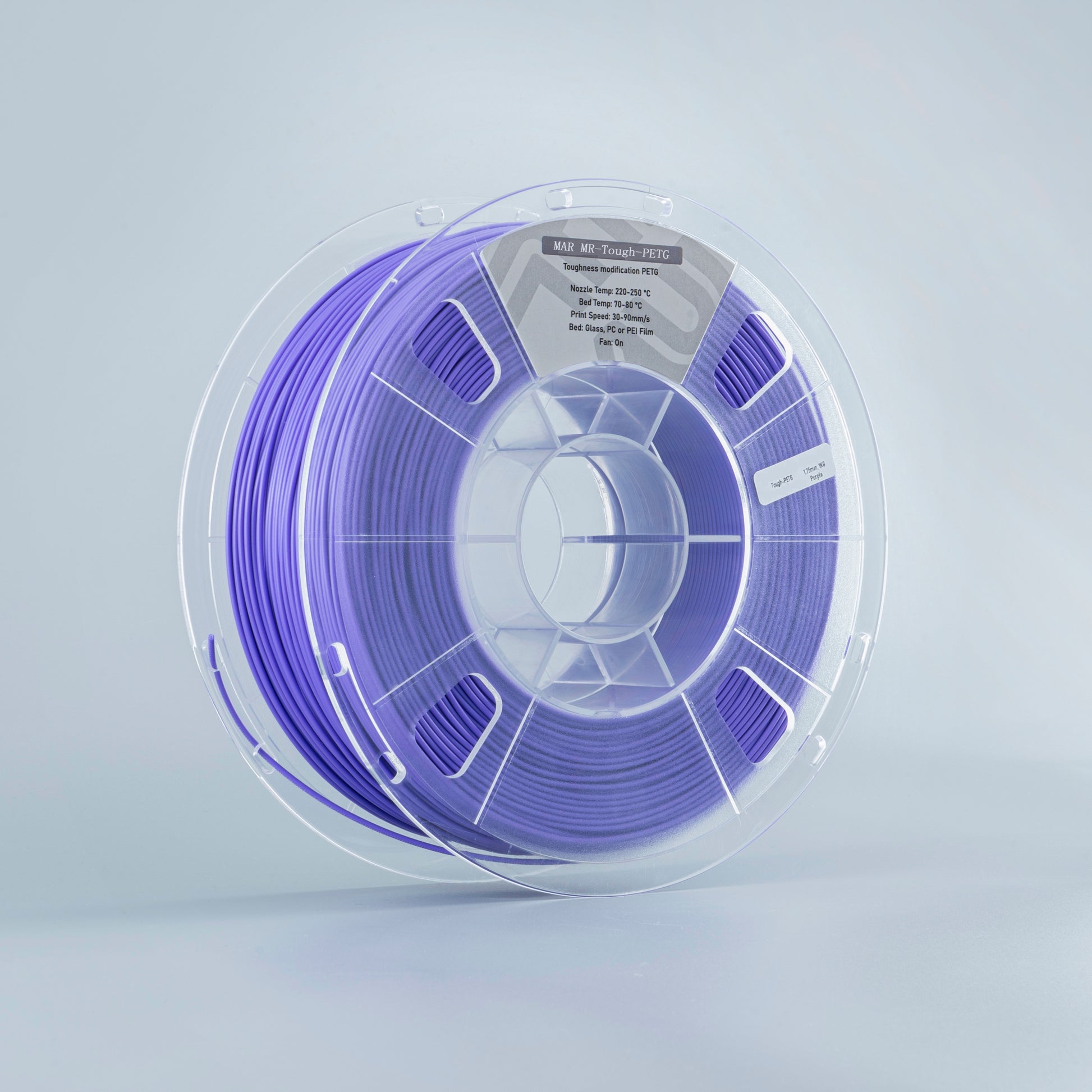

Mayrc Purple 1.75mm 3D Printer Filament High Flow Toughness Filament Consumables Easy Print 3D Printing Materials

Mayrc Purple 1.75mm 3D Printer Filament High Flow Toughness Filament Consumables Easy Print 3D Printing Materials

Couldn't load pickup availability

Mayrc Purple 1.75mm 3D Printer Filament High Flow Toughness Filament Consumables Easy Print 3D Printing Materials

Specification:

|

Model No |

MR-Tough-PETG |

Cable Net Weight |

1kg/roll |

|

Color |

Purple |

Nozzle Temperature |

220-250℃ |

|

Bed Temp |

70-80℃ |

Print Speed |

30-90mm/s |

|

Bed |

Glass,PC or PEI |

Cooling fan speed |

On |

|

Cable Size |

1.75mm |

Feature |

High flow |

|

Recommended support material |

MAR™ MR-PVA |

||

|

Recommended Nozzle Diameter |

0.2-1.0mm |

Raft separation distance |

0.2-0.25mm |

|

Retraction distance |

2-5mm |

Retraction speed |

1800-3600 mm/min |

Notice:The bonding between MR-Tough-PET and the PC bottom plate is very strong. When printing a larger bottom surface, the distance between the first layer of the model and the bottom plate can be appropriately adjusted.

Product Description:

MR-Tough-PETG is a tough PETG specially developed for FDM3D printing technology, and at the same time it has advanced printing performance by improving the fluidity of the material. Compared with PLA, it has better mechanical strength and heat resistance

Product Advantages:

1.High Impact Resistance

The notched impact strength of MR-Tough-PETG is increased to more than twice that of ordinary PETG without affecting the interlayer bonding strength in the Z-axis direction

2.Easy to Print

MR-Tough-PETG has excellent material fluidity and good molding effect, which can be printed first in most printers.

Material Properties:

|

Property |

Testing method |

Typical value |

|

Density |

ISO 1183 |

1.24 g/cm³ |

|

Melting Temperature |

ISO 11357 |

78℃ |

|

Melt index |

220℃, 2.16kg |

13.2g/10min |

|

Determination of temperature |

ISO 75: Method A |

73℃ (1.80MPa) |

|

ISO 75: Method B |

78℃ (0.45MPa) |

|

|

Tensile strength(X-Y) |

ISO 527 |

40.3±0.6 MPa |

|

Young’s modulus(X-Y) |

1780±80MPa |

|

|

Elongation at break (X-Y) |

10.1±0.6 % |

|

|

Bending strength (X-Y) |

ISO 178 |

62.8±0.4 MPa |

|

Bending modulus (X-Y) |

1919±54 MPa |

|

|

Charpy impact strength (X-Y) |

ISO 179 |

13.9±23KJ/㎡ |

Specimens printed under the following conditions: Nozzle temp 300°C, Bed temp 80℃, Print speed 45mm/s, Infill 100%, Infill angle ±45°

Disclaimer:

The typical values presented in this data sheet are intended for reference and comparison purposes only. They should not be used for design specifications or quality control purposes. Actual values may vary significantly with printing conditions. End- use performance of printed parts depends not only on materials, but also on part design, environmental conditions, printing conditions, etc. Product specifications are subject to change without notice.

Each user is responsible for determining the safety, lawfulness, technical suitability, and disposal/recycling practices of Mar materials for the intended application. Mar makes no warranty of any kind, unless announced separately, to the fitness for any use or application. Mar shall not be made liable for any damage, injury or loss induced from the use of Mar materials in any application.

Share